So it was the first Tuesday after having an induction, pretty excited as it gave an opportunity to test the printing workflow with a simple task (or what I thought to be).

There's something pretty exciting about thinking of something, designing it on computer and seeing it being 3D printed – all in one day. With the help of Georgie in the Art Room at Kathryn Syme Library, it became a reality.

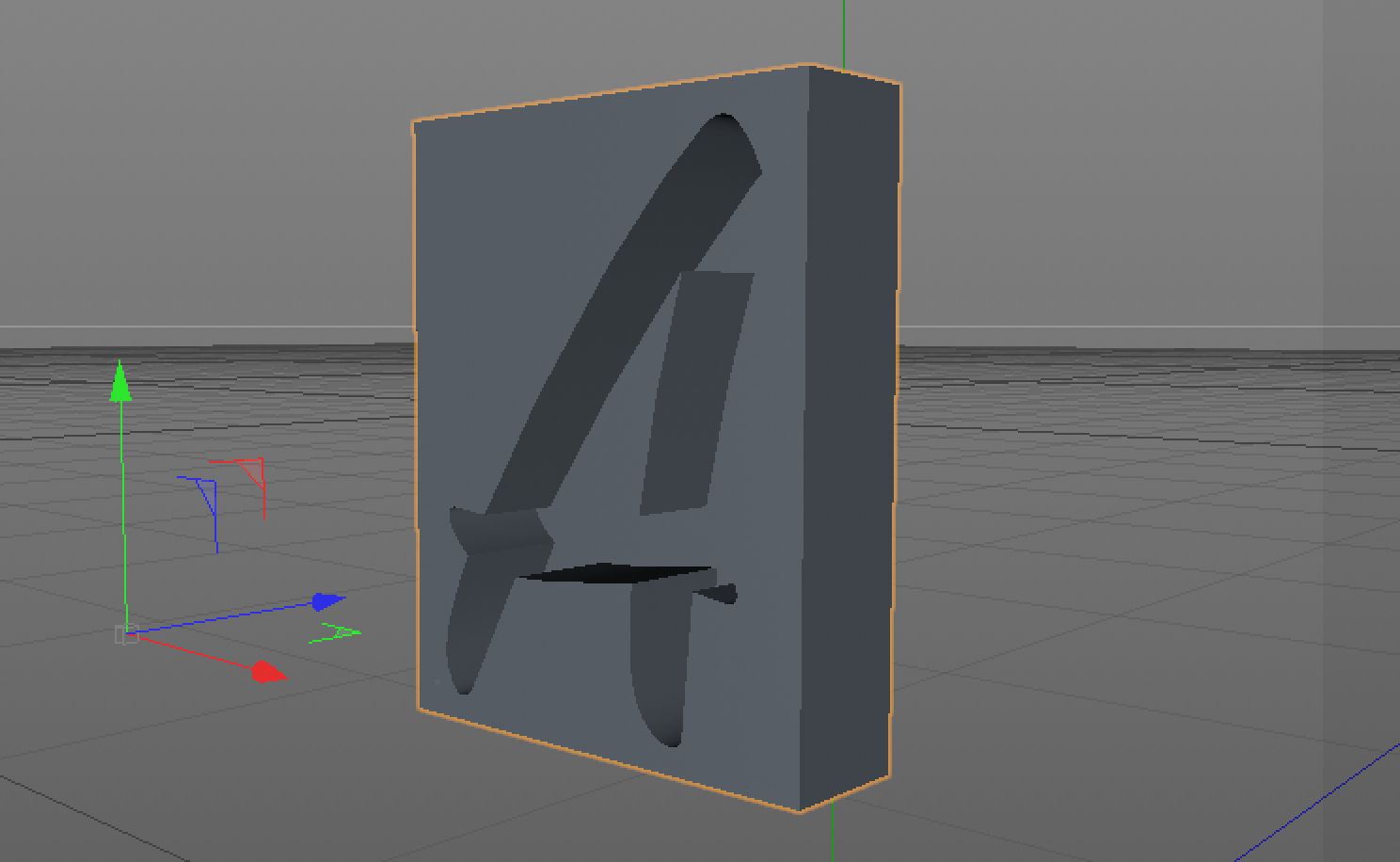

That morning I quickly created a one sided mould. Little steps.

The idea was to freeze an A with this printed mould, unfortunately it didn't work out. More on that later.

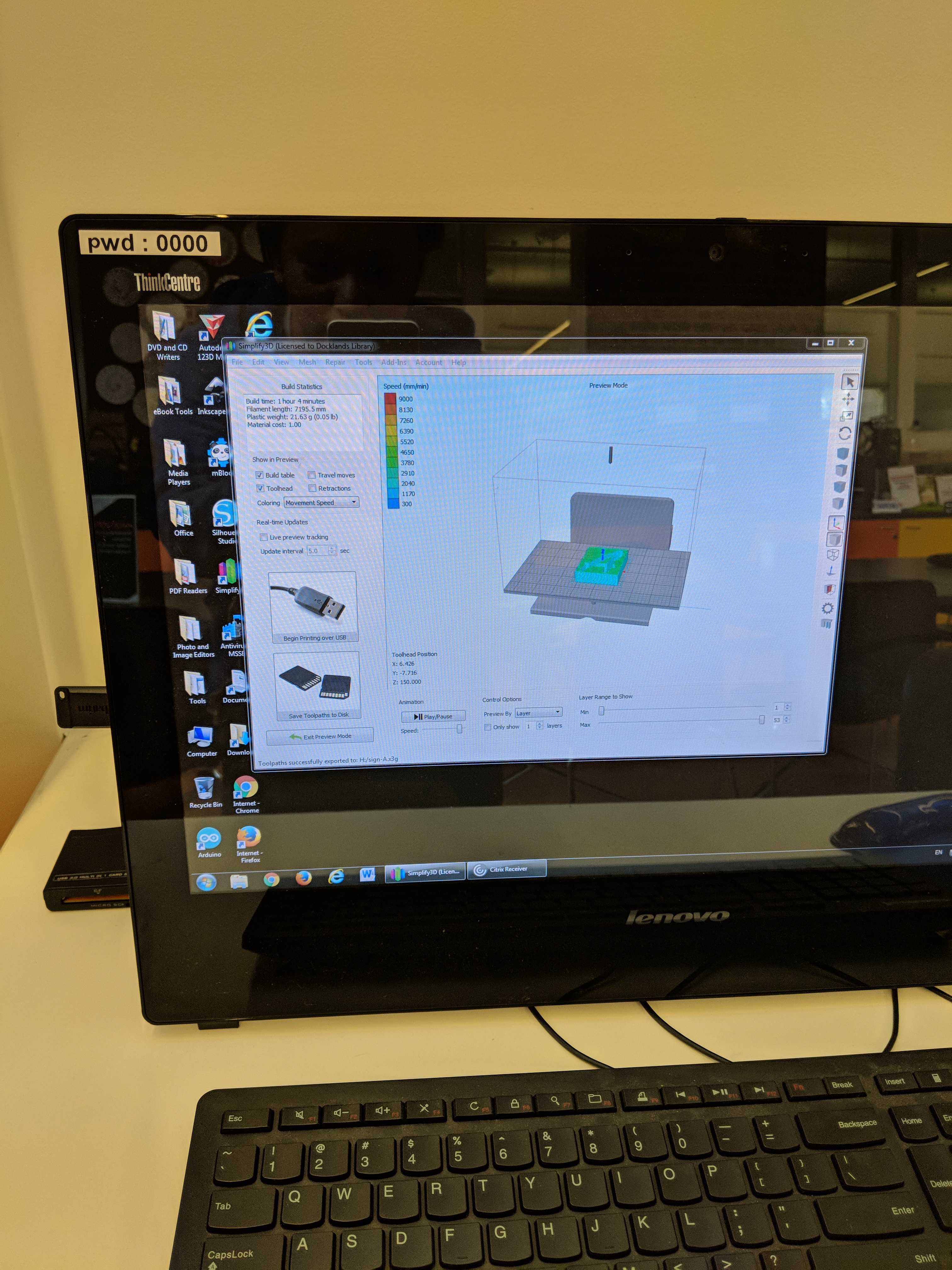

Setup used Simplify3D.

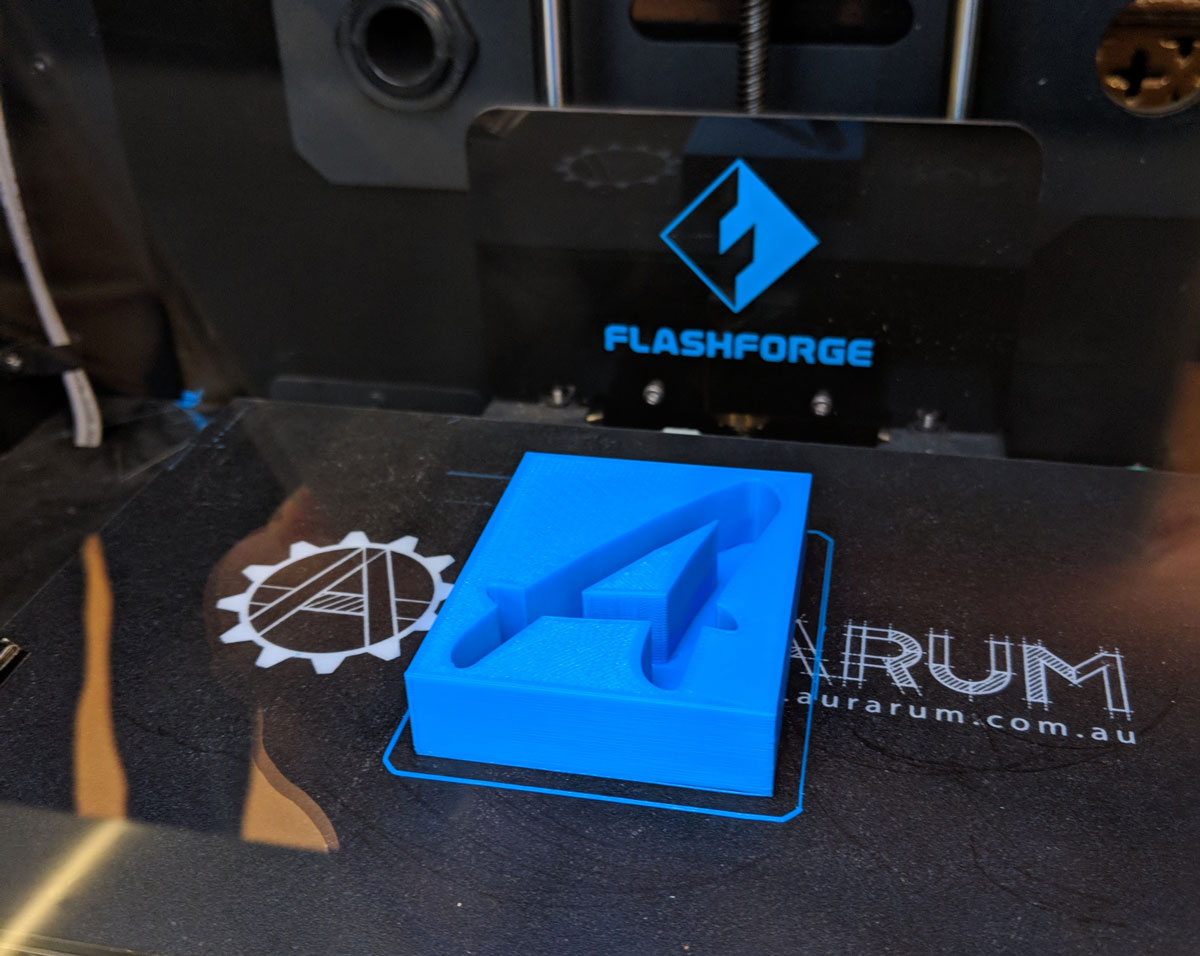

And here we go, printing...

There's something quite satisfying about watching something being created so precisely.Printed 28 March 2018

Time: 1hr 6min

Typeface: Sign Painter

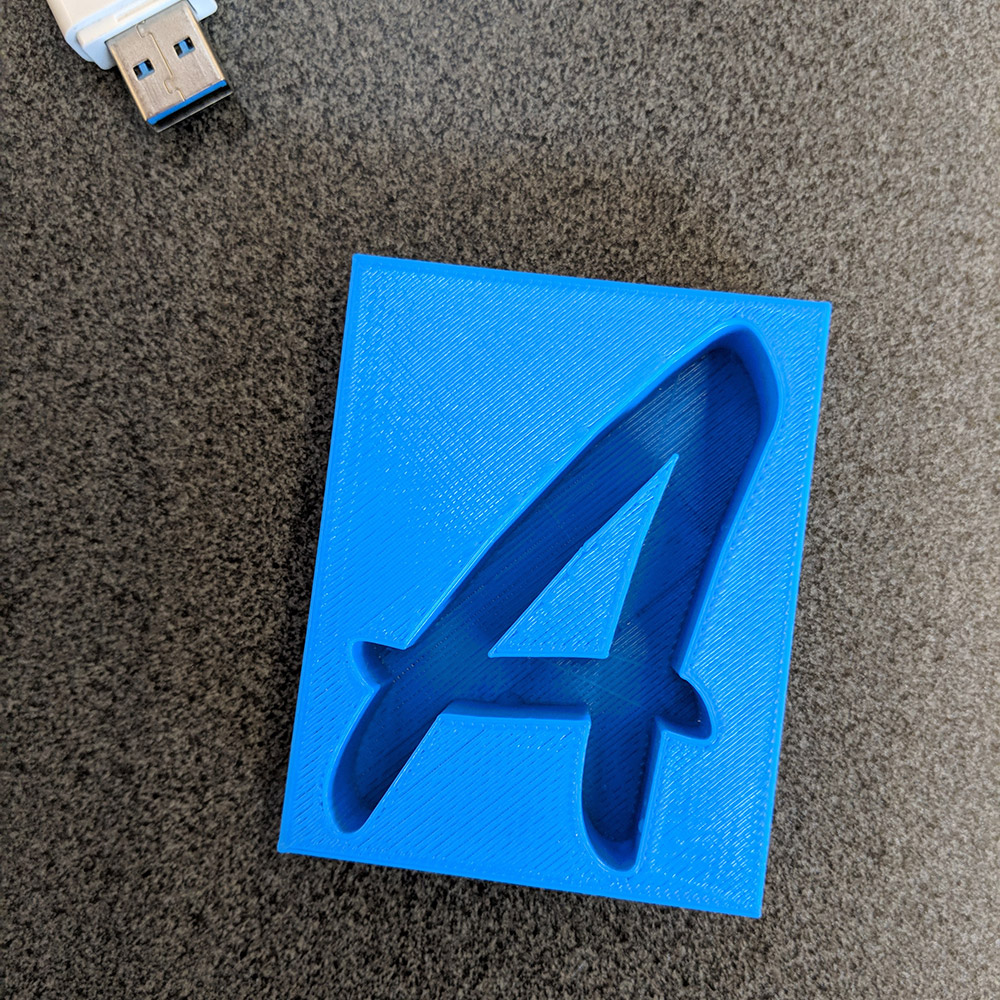

And the finished product.

Pretty stoked with this, turned out great (at fast speed).

So next up, is it waterproof? Found out pretty quickly it wasn't. But only in one area – where the apex of the counter meets the base. Glimmer of hope!

We melted wax and poured it in. Waterproof done. Killing it.

And now creating ice with this form. Pretty quickly we found we couldn't take it out of the form. Firstly because the mould is so rigid and also because it didn't have a lining of mould release sprayed onto the mould. I should've known this.

The layering of printed plastic also created a place the ice can firmly hold onto.

So we resulted in putting the plastic form into warm water, hopefully the mould will warm up and release the ice shape but I guess plastic isn't a good conductor or heat either.

So this is what happened when it eventually came out.

Failed.

Ok so it's a good thing I didn't skip ahead too much and print that two part mould I created the night before. I was too keen printing a mould I didn't realise the restraints associated with the material.

Quickly learning.

–––

Further notes:

• So, it looks like it's back to silicon moulds then, but at least I can still print the letters and cast them into these moulds. Need to adress the 'print' surface and smooth out.. (?)